Robot expertise

Vision expertise

Automation expertise

Robot-guided handling

Robot-guided handling

Put your automation project in our hands with confidence. We develop suitable solutions for handling, but also for various robot-assisted assembly tasks.

"Our unique selling point is our expertise in industrial image processing paired with robotics."

Lars Neumann, Teamleiter Projektmanagement

Performance! Hello Open Roads

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Environmental Friendliness

Endless Possibilities

Robot-guided handling

Transporting parts in and out of a production facility is often very stressful for people. We offer solutions through the targeted use of robotics for new or existing production facilities to relieve your employees and increase efficiency. We use the latest engineering tools, from concept to implementation. We tailor the solution perfectly to your requirements. A palletizing solution can be perfectly combined with a prior inspection of the parts.

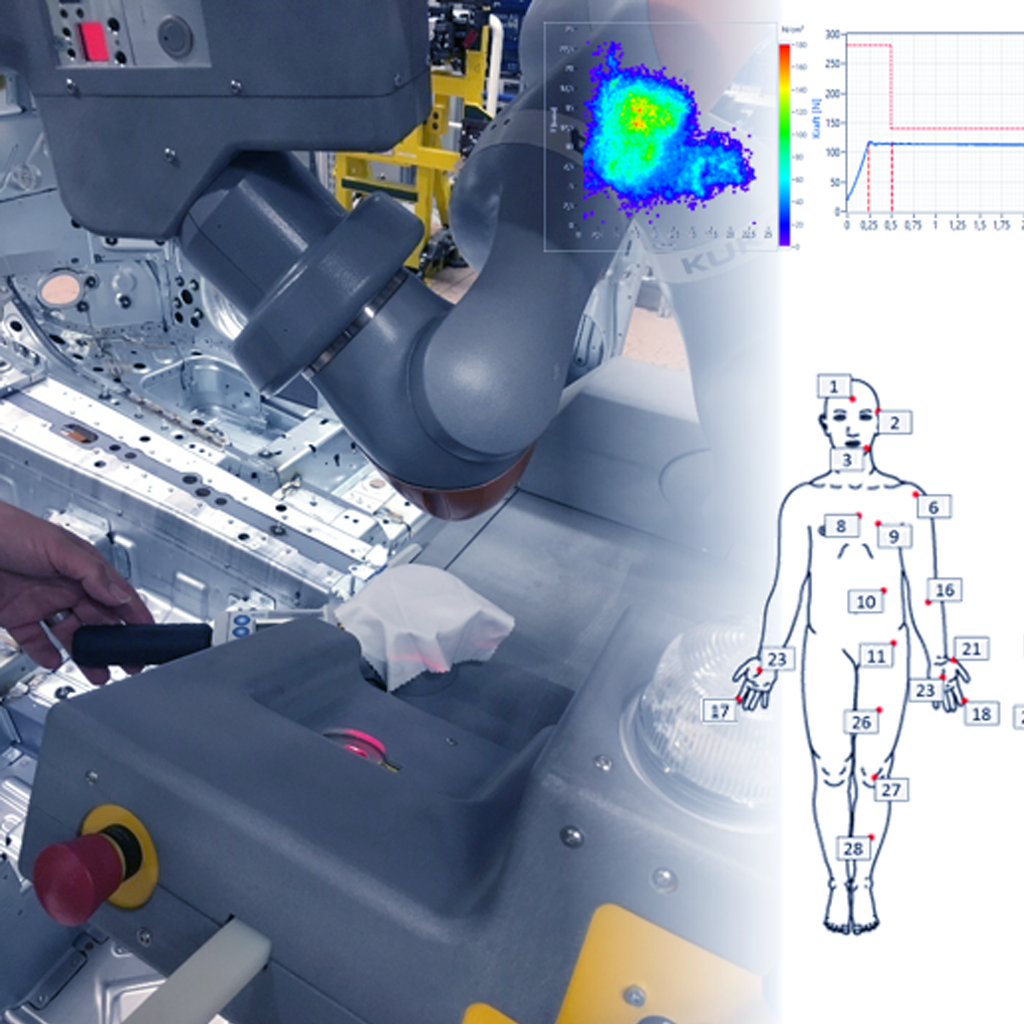

Robot-assisted assembly

Robot technology allows a high degree of flexibility in modern production plants. Our in-depth expertise in automation technology, robotics and industrial image processing provides you with solutions for the mechanical joining of components, including integrated component inspection if required. With cycle times ranging from a few seconds to several minutes and a high variance of production parts.

Mobile handling & assembly

In some production scenarios, a stationary robot is not worthwhile or more flexibility is required to avoid expensive conversion work on existing machines. One possible solution is a combination of a mobile platform and 6-axis kinematics. Particular attention is paid to safety in order to avoid endangering human colleagues. We offer various solutions for weights from a few grams up to 300 kg part weight. Our partners OMRON and KUKA supply the components for this.

Do you want to automate your handling or assembly processes?

Here you will find the ingredients you need for successful automation…

Conceptualize & plan

With our tools for simulation and visualization, concepts can be defined and verified at a very early stage with regard to cycle times or required space using a digital twin.

Key components

Our preferred components include cobots, heavy-duty robots, high-speed and mobile robots. When it comes to safety, end-of-arm, image processing and control technology, we rely on our own innovative systems and those of our partners.

Control & visualize

Above all, successful automation includes clear visualization, options for error analysis and rectification, as well as maintenance and servicing scenarios. Whether remotely or online on the system.

Manage projects efficiently

At the beginning of a project, there is a clear coordination of our customer's expectations and a detailed description of our solution. Our project managers put the customer's wishes first.

Produce safely

Our in-house safety engineers pay particular attention to safety when designing your solution. From risk assessment to CE conformity. In any production environment.

Solutions for the cleanroom

Robotics in cleanrooms must meet special requirements. Our robot solutions meet EU GMP standards and also work reliably in ESD-protected environments.

Tell us your requirements.

We meet your requirements with extensive expertise in the entire automation technology value chain. We focus on sustainable, scalable, user- and service-friendly concepts.