The ergonomically difficult task of headliner assembly is a good example of the benefits of sensor-guided robot applications in assembly. A 6-axis heavy-duty robot measures itself against the vehicle with a sensor system from AI° and installs the headliner in a vehicle with optimized tolerances. Repeatable accuracy despite existing tolerances in the process.

Initial situation

Volkswagen is also aiming for a high degree of automation in assembly. The challenge is also to deal with the strong fluctuations in the vehicle’s position, which must be compensated for in an automated process. In our example, a headliner is being fitted, which in conventional manual processes involving several workers has to be inserted through the front and then pressed into the catches with one worker lying on his back. Ergonomically not a good situation.

Implementation

The AI° system for robot position optimization is used to detect the position and orientation of the vehicle. The robot, which is equipped with a component gripper, receives its correction data directly from the sensor system in all its degrees of freedom and installs the headliner 100% reliably in the respective roof of the vehicle.

Customer benefits

By automating ergonomically unfavorable workstations, employees are spared and can be deployed on other value-adding, more complex tasks that are difficult to automate.

Procedure

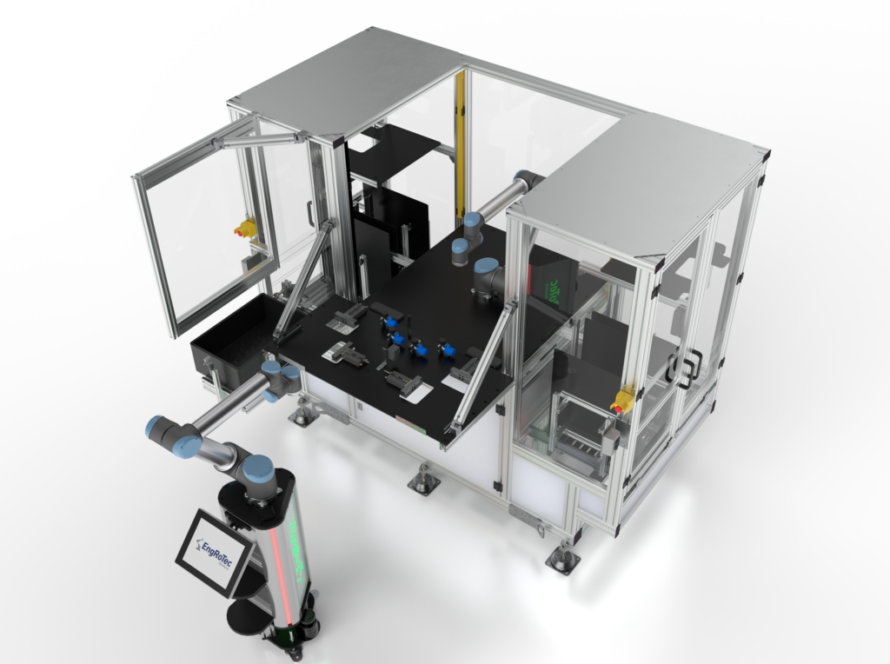

AI° VISIONSCANNER2 light section sensors with KUKA heavy-duty robots.

Parameters

- Cycle time 120 seconds

- Measuring speed 200ms

- Several vehicle variants possible